Researchers have developed a sensor that can measure wear on automobile wheels with high accuracy on a real-time basis. By having done so, it will be possible to select the optimal time to change wheels.

Automobile wheels get depreciated by time as they are on the road. As far as wear is concerned, people used to look and try to decide whether or not it is the right time to change wheels. In order to have a more accurate and sensitive measurement about the wheel change process, electric engineers in Duke University developed a special sensor. The device is designed in co-operation with Fetch Automotive Design Group, can measure differences in millimeter units with a 99% accuracy rate.

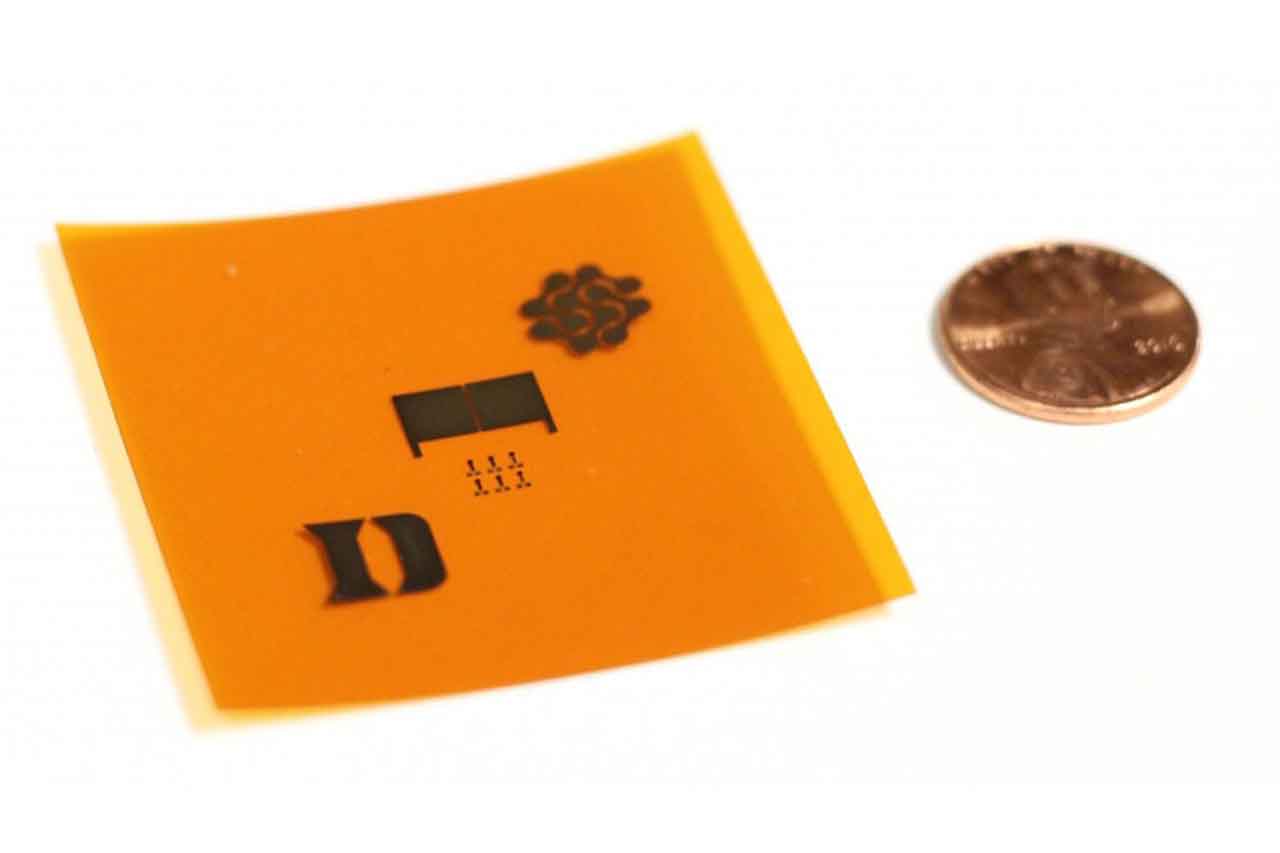

The sensor being attached to the inner surface of the wheel consists of two electrodes made of carbon nanotubes. There exists an electric field transaction due to vibrations among the very closely distributed electrodes located on a flexible polyamide. Thus, the electric field is accumulated on the body of this sensor. By measuring the disorders and parasites in the field, the sensor measures wear level on the wheel.

Even though this technology is not quite successful on metallic materials, it works perfectly on wheels and other rubber-based polymers. Being still in development and R&D, the sensor is expected to be sold as being already placed in the wheels.

Contributor: Egemen ERES